- Email: sxtao@hnjsx.com.cn

- Tel: +86-371-55628659

Basic configuration of powder tank: 2 DN500 quick-open manholes, 2 DN100 ash outlet valves, 4 DN50 air inlet valves, 1 safety valve, 1 pressure gauge, 1 pressure discharge valve, secondary air inlet device, air bag liquefaction bed (V-type two-bin type), ash outlet air inlet pipeline, etc.

The tank has a double cone, inward-tilting horizontal structure, with two bins for simultaneous air intake and discharge, and two bins for simultaneous charging.

Basic configuration of powder tank: 2 DN500 quick-open manholes, 2 DN100 ash outlet valves, 4 DN50 air inlet valves, 1 safety valve, 1 pressure gauge, 1 pressure discharge valve, secondary air inlet device, air bag liquefaction bed (V-type two-bin type), ash outlet air inlet pipeline, etc.

The tank has a double cone, inward-tilting horizontal structure, with two bins for simultaneous air intake and discharge, and two bins for simultaneous charging.

1. Connect the discharging pipe to ensure reliable sealing

2. Close the discharge valve, external wind valve and secondary wind valve.

3. Connect the air inlet pipe to ensure reliable sealing; open the air inlet valve, turn on the external air source and inflate the air chamber in the tank; when the pressure in the tank - i.e. the pressure gauge reading reaches 2 BAR, open the discharge valve (if the pressure continues to rise, it means the pipe is blocked). The discharge pressure should be maintained between 1.8 and 2.4 BAR. When unloading is complete and the pressure in the tank drops to 0.2 BAR, open the secondary air ball valve so that the ash unloading pipeline is all unblocked.

4. Turn off the air source after unloading; open the pressure discharge valve to discharge the pressure inside the tank.

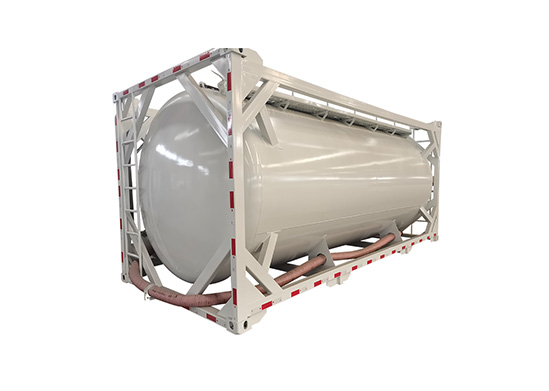

| Product | 20feet bulk cement container tank | |||||||

| Design standard | GB/T 1413-2008 series 1 container classification , size and mass gross | |||||||

| Tank body : made of steel Q345R, 4mm thickness ; dish end: steel Q 345R, 4mm thickness; | ||||||||

| Gross weight | 33,000Kg | payload | 29,100 Kg | Curb weight | 3,900Kg | |||

| Medium | Bulk cement | |||||||

| Overall dimension | L*W*H 6058mm*2438mm*2591mm | |||||||

| Design pressure | 0.2MPa | Air supply | ≥ 8 | |||||

| Test pressure | 0.3MPa | Allowable stacking weight 1.8g | 192,000 kg | |||||

| Design temperature | -19 to +80 ℃ | Manhole DIA | 500mm | |||||

| Air source pressure | 0.25-0.3 MPa | Air-inlet DIA mm | 2 " male adaptor | |||||

| Outlet DIA mm | 4" male adaptor | Average discharge speed | Cement: 2t/min | |||||

| Remnant Ratio | Lower than 100kg | |||||||

| Tank barrel | ||||||||

| Volume | 22,000L | Inner DIA | 6000*2420 | |||||

| Density | 1250kg/m3 | Compartment | 2 pcs | |||||

| Manhole | 2 pcs | Quick-open type | ||||||

| 1) Tank shell and Dish end: Q 345R ; | ||||||||

| 2) Top side rail, end rails, internals, walkway : Q 235; | ||||||||

| 3) Corner posts, end arc support rings: Q 345B; | ||||||||

| 4) Corner fittings: SCW 49; | ||||||||

| 5) Pipe: 20-GB 8163 | ||||||||

| 6) Valves: cast steel | ||||||||

| 7) Ventilation membrane: Synthetic fabric | ||||||||

| 8) Screws and bolts: Q 235 | ||||||||

| 9) Tank construction : factory standard | ||||||||