- Email: sxtao@hnjsx.com.cn

- Tel: +86-371-55628659

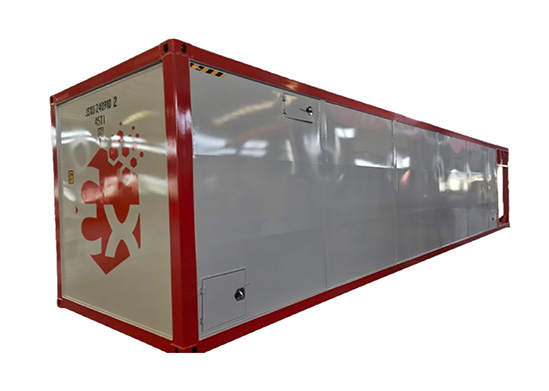

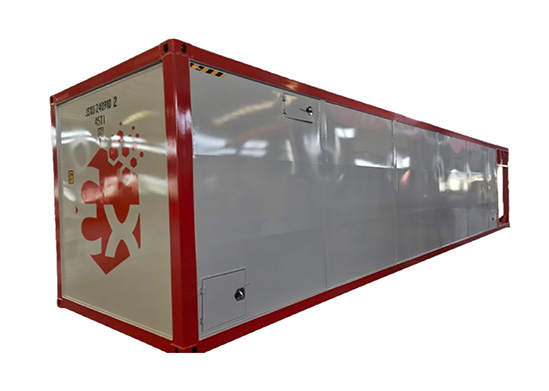

40ft Emulsion Tank Container can carry out production under special technical specifications according to the special requirements put forward by customers.For example, different requirements for: paint type/color/thickness, steel thickness, corner fitting requirements, etc.

Introducing our 40-foot chemical emulsion tank container, designed with a robust frame and integrated sealing panels to prevent liquid leakage, adhering to local regulations for enhanced environmental safety. This large-capacity tank is ideal for various industrial applications, offering ample storage for your chemical needs. To enhance convenience and usability, we have included pre-drilled holes, allowing customers to easily install their own pumps according to specific requirements. Our innovative design not only maximizes storage efficiency but also ensures compliance with safety standards, making it a reliable solution for businesses focused on sustainability and operational excellence. Choose our chemical emulsion tank container for a flexible, eco-friendly, and efficient storage solution.

40ft Emulsion Tank Container’s frame is made of rectangular structural steel, which is light in weight and strong in strength, and is suitable for transit transportation by sea, road, and railway. It is mainly suitable for road transportation of large-scale container-type flat cars and ocean-going ships berthing containers for transporting chemically corrosive liquids.

| transport medium | emulsion |

| Overall dimensions (mm) | 12192*2438*2891 |

| self weight (kg) | 12000 |

| Production cycle | 1 unit/30 working days |

| Volume (can guarantee 47.5 cubic meters of liquid cargo) | 47.5 square meters |

| Tank size (mm) | 10500*2300*2300 |

| warranty period | one year |

| ItemItem | Specification |

| Tank material | Q235 carbon steel/6.0mm |

| Beam material | Q235 carbon steel |

| shape | Cylindrical |

| Curb weight (kg) | 12000 |

| Head thickness | Q235 carbon steel/6.0mm |

| Tank thickness | Q235 carbon steel/6.0mm |

| anti-wave board | There are 4 rice-shaped semicircle 4mm supports in the tank |

| Operation room | Patterned aluminum alloy bottom plate, thickness 4mm |

| Container top | 4mm carbon steel plate seal |

| Manhole assembly | DN500/2 pieces |

| Flange interface | DN100 |

| Inlet | DN100 |

| Discharge valve | DN100 |

| Quick coupling | DN100 |

| container frame | Q345/150mm*150mm |

| Container bottom | 4mm carbon steel plate seal |